Precision Power Restored: Your Industrial Gearbox Repair & Machining Experts

The Full-Service Difference: Rebuilding Your Critical Equipment

When a gearbox fails, your entire operation stops. At A+ Quality Gearbox Repair, we don’t just replace parts; we leverage our comprehensive in-house machine shop capabilities to deliver complete gearbox repair that restores—and often improves—your equipment’s original performance.

Our certified technicians follow a rigorous process to ensure precision at every step:

● Detailed Inspection & Diagnosis: We begin with a full teardown, cleaning, and Root Cause Failure Analysis. Using advanced diagnostic tools, we identify the exact cause of failure (e.g., bearing failure, lubrication issues, gear wear, or misalignment).

● Component Restoration: Critical components like housings and shafts are inspected. We utilize services like welding, metalizing, and precision grinding to repair cracks, restore worn bearing journals, and renew seal surfaces, preventing costly housing replacement.

● Precision Reassembly: The unit is carefully rebuilt using high-quality replacement parts, including premium-grade bearings and seals. We check and set all critical tolerances, backlashes, and tooth contacts.

● Performance Testing: Every rebuilt gearbox undergoes a no-load spin test to monitor vibration, noise, and temperature, guaranteeing it is ready for immediate heavy-duty service upon return.

Gear Manufacturing: Beyond Replacement

What truly sets a full-service machine shop apart is the ability to handle parts that are obsolete, severely damaged, or custom-designed.

● Legacy & Custom Jobs: For discontinued or highly specialized gearboxes (often found in older mixers, mills, or specialized processing equipment), we utilize reverse engineering. Our machinists can take measurements from a worn or broken component and manufacture a brand-new gear or shaft to precise specifications, often with materials or hardening that exceed the original OEM quality.

● Core Capabilities: Our machine shop is equipped with gear hobbers, precision grinders, and CNC lathes, allowing us to fabricate and custom-finish spur, helical, spiral bevel, and worm gears up to large industrial sizes, ensuring perfect fit and function when OEM parts are unavailable.

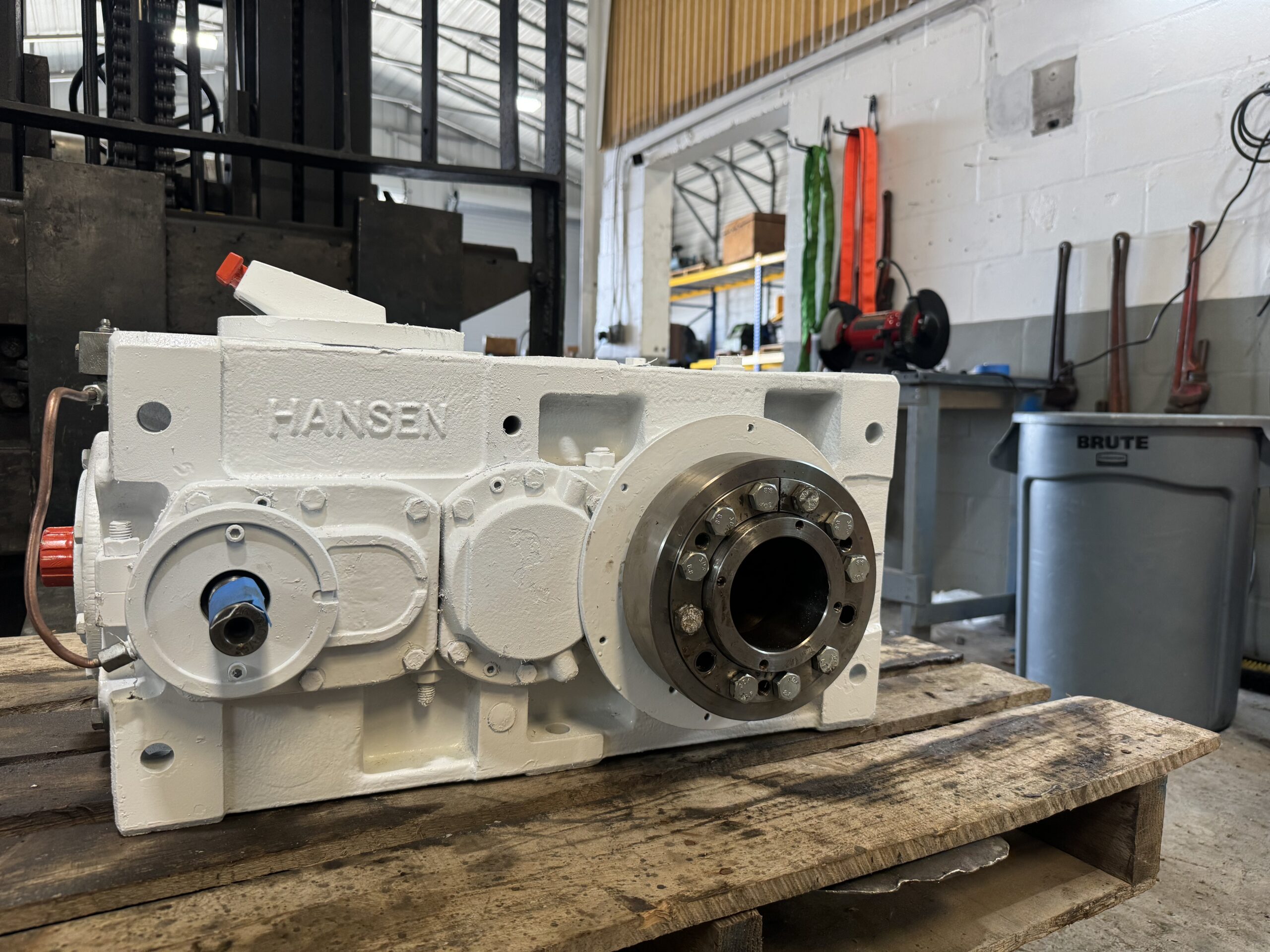

We Repair All Major Gearbox Brands

Our technical expertise is not limited by brand. We service, repair, and upgrade industrial gearboxes and speed reducers from virtually all foreign and domestic manufacturers, including but not limited to: ● Falk / Rexnord

● Flender / Siemens

● Dodge

● Hansen

● Philadelphia Gear

● Lufkin

● SEW Eurodrive

● Sumitomo

● David Brown

● Foote-Jones

No matter the brand, size, or age of your industrial power transmission equipment, we provide the certified expertise and in-house machining to minimize your downtime and maximize your asset lifespan

Ready to get your critical equipment running better than new?

Contact us for a free quote on your gearbox repair

(626)472-3375

Rene@AQualityGearboxRepair.com